Rumored Buzz on Digital Printing

The positive plate, with its smooth surface, attracts oil-based inks and pushes back water. In contrast, the adverse plate, with its harsh texture, soaks up water and pushes back oil. Rubber rollers are after that used to move the image from the plate to the corrugated surface area.

Corrugated paper can in some cases verify to be a tough surface area to print on, yet Litho prints to a separate surface area and is after that laminated flooring to it, making it easy to publish top notch images. It can be very constant, also for long runs. Actually, the much more you print, the less costly the prices end up being for Litho.

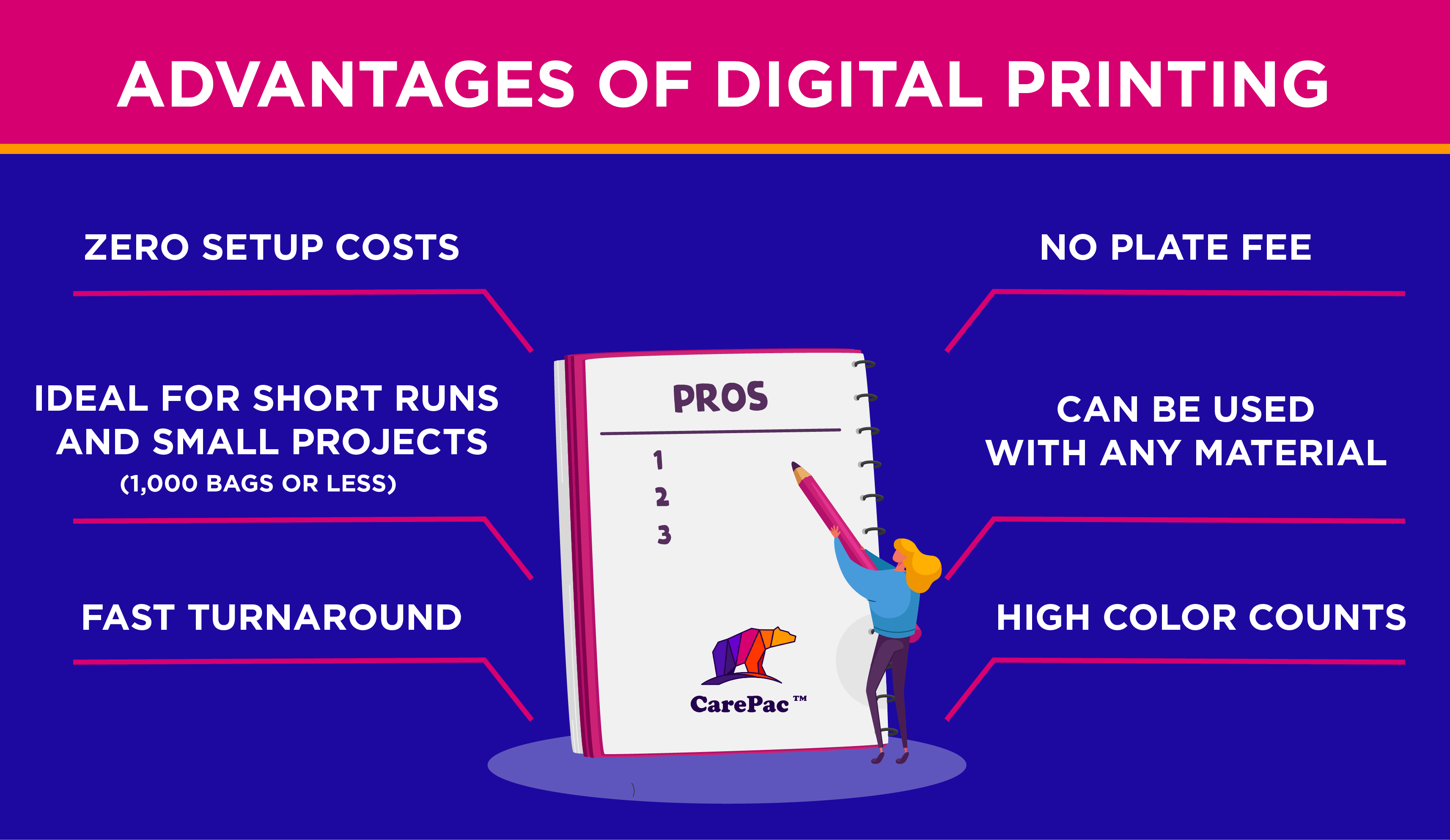

What Litho doesn't give you is precisely what Digital does, modification. Pricey established up Longer turn-around No Variable Data Printing Smaller shade gamut, colors can be much less bright Digital printing is the procedure of printing electronic photos directly onto the corrugated substratum using a single-pass, direct-to-corrugate strategy.

Some Known Incorrect Statements About Digital Printing

This streamlines the process and opens up various advertising and style opportunities!:. Typical printing approaches like Offset Printing have actually been the status for some time, and one of the largest reasons is that at big volumes, it wins on expense. That's if you intend to make use of a solitary style for all of your product packaging - those days are over.Offset Printing requires time and cash to develop a Printing Plate, while Digital Printing enables you to just post an art data( as many as you desire )to the Press. Variable Information Printing (VDP)Print-on-demand Special item designs Seasonal+Promotional messaging Economical brief productions Quicker turn-arounds If your project has a solitary design, Litho might be a far better option because of the scaling prices of manufacturing. There are other factors to choose Litho, however as discussed previously, the days of a one-size-fits-all design are over. That suggests that all brand names need to readjust their method as soon as possible. When they acquire their goods, clients have an appetite for marketing experts to produce this personal experience for them-and electronic aids you to do this. Today, a lot of brand names underuse print customization due to the fact that they are just not aware of the practice's possible advantages and that electronic printing is the method to obtain there. These are several of the most dependable and efficient electronic printers on the market.

We provide whatever from simple brown delivery boxes to advanced, high-graphic printed point-of-purchase display screens and whatever in between. They vary in dimension and technology, however they allow you to post art check this site out files directly to the press, as opposed to creating printing plates. Digital Printing is when you print a digital-based picture onto some type of print media.